Featured Service

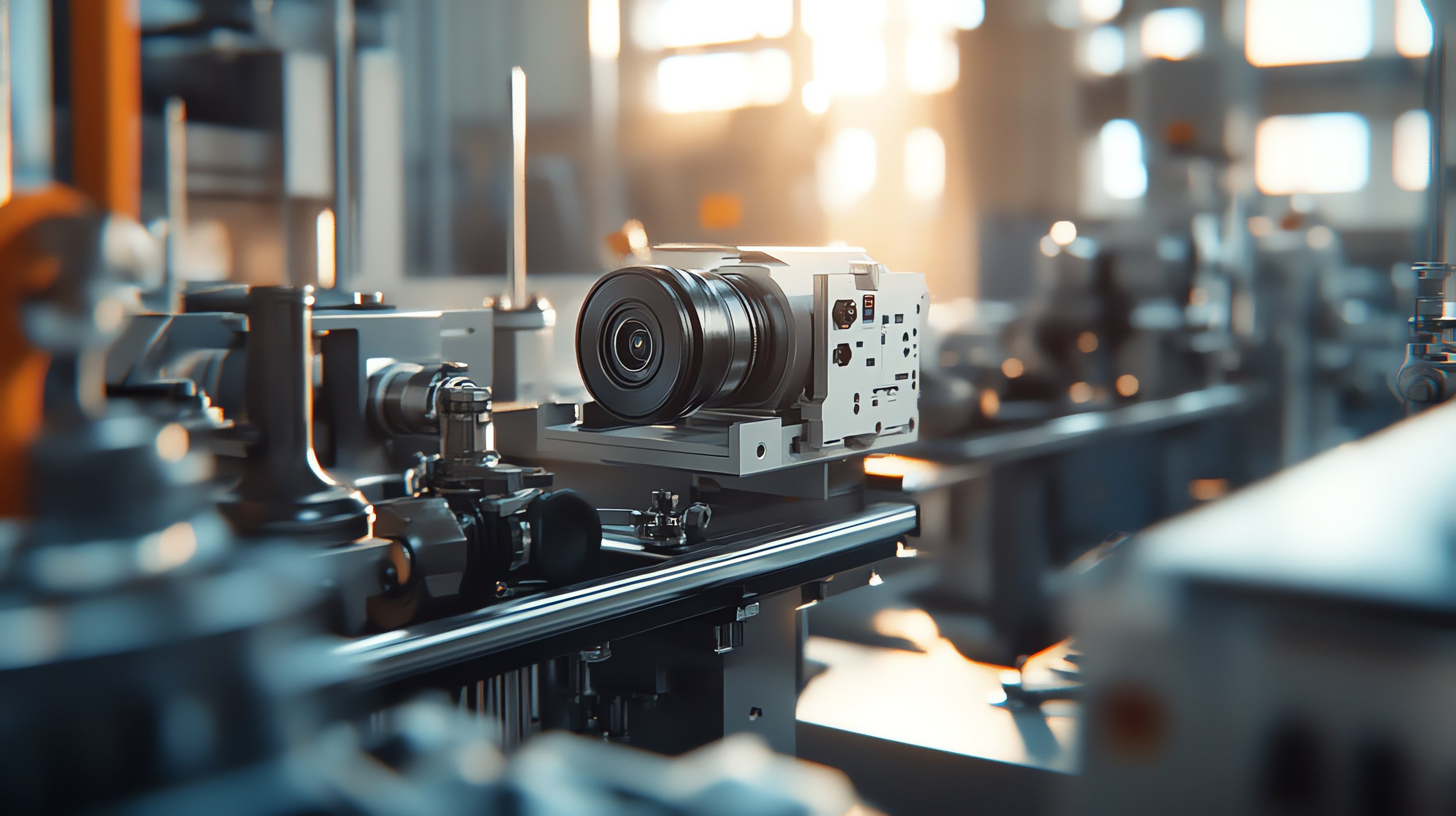

Vision & Inspection

Automation Services

Who We Are Industries Services Approach Success Stories Awards Blog Careers Contact UsDelivering precision, efficiency and quality for modern manufacturing.

Pieper Automation is a premier systems integrator specializing in solutions for challenging applications. With over 30 years of machine vision experience, we offer expertise in automating and enhancing processes, whether for machine cells, production lines, or manufacturing plants. Our industrial vision system experts excel in all aspects of vision technology, applying skills in cameras, lenses, lighting, and coding to deliver optimal solutions. If you're considering a vision system to improve your process, our engineers are ready to design, build, and install a tailored solution for your application, industry, and environment.

VISION + inspection SOLUTIONS

Working with our Custom Machine engineering team we can design, manufacture, and build any ancillary equipment to support your vision application, machine cell or production line. The complexity of our project experience ranges from a single-camera system to a multi-camera system carrying out multiple inspection tasks.

Pieper Automation has a fully equipped Innovation Center to mockup and validate the setup for your application. We use our hi-tech lab to not only keep up with the latest in camera and lighting technology, but also to help customers design an optimal vision solution setup including camera, lens, & lighting selection. We also mockup and validate part presentation to ensure both application success and assurance that your vision-inspection system will be robust, effective, and cost acceptable.

Improved Product Quality

Consistent Quality Assurance: Vision systems detect defects, inconsistencies, or deviations in real time, ensuring that only high-quality products reach customers.

Zero Human Error: Automated systems eliminate mistakes caused by manual inspection fatigue or oversight.

Increased Efficiency and Cost Savings

Faster Inspections: Vision systems can inspect multiple products per second, far outpacing human inspection speeds.

Reduced Bottlenecks: Streamlined inspection processes improve overall production flow.

Lower Rework Costs: Identifying defects early reduces costs associated with reworking or scrapping defective products.

Minimized Waste: Vision systems can optimize material use by identifying precise defects and avoiding unnecessary disposal.

Reduced Labor Costs: Automation replaces or supports manual inspection, lowering workforce costs.

Enhanced Compliance and Traceability

Regulatory Compliance: Ensures products meet industry standards, avoiding fines or recalls.

Data Logging: Records inspection results for traceability and quality audits.

Real-Time Feedback and Process Optimization

Immediate Alerts: Detect and report defects as they occur, enabling quick corrective actions.

Process Optimization: Insights from vision systems help identify production inefficiencies and improve processes.

capabilities

New System Design + Fabrication

Optimization of Existing Systems

Feasibility Studies

PLC and Machine Integration

Complete Turn Key Systems

System Troubleshooting

OEM Partnerships

solutions

Sorting & Counting

Defect Detection

Contamination Detection

Label Reading + Verification

Code Reading + OCR

Gauging + Measurement

Vision Guided Robotics

Smart Cameras

PC Based Systems

TECHNOLOGIES

Area Scan

Line Scan

OCR

Thermal

Laser Profilers

3D

Multi Spectral

Hyper Spectral

AI + Machine Learning

industries served

Food + Beverage

Building Materials

Foundry and Machining

Packaging

Pharmaceutical

Manufacturing

Consumer Products

Recycling

Pulp + Paper

…and more.